About clean eggs

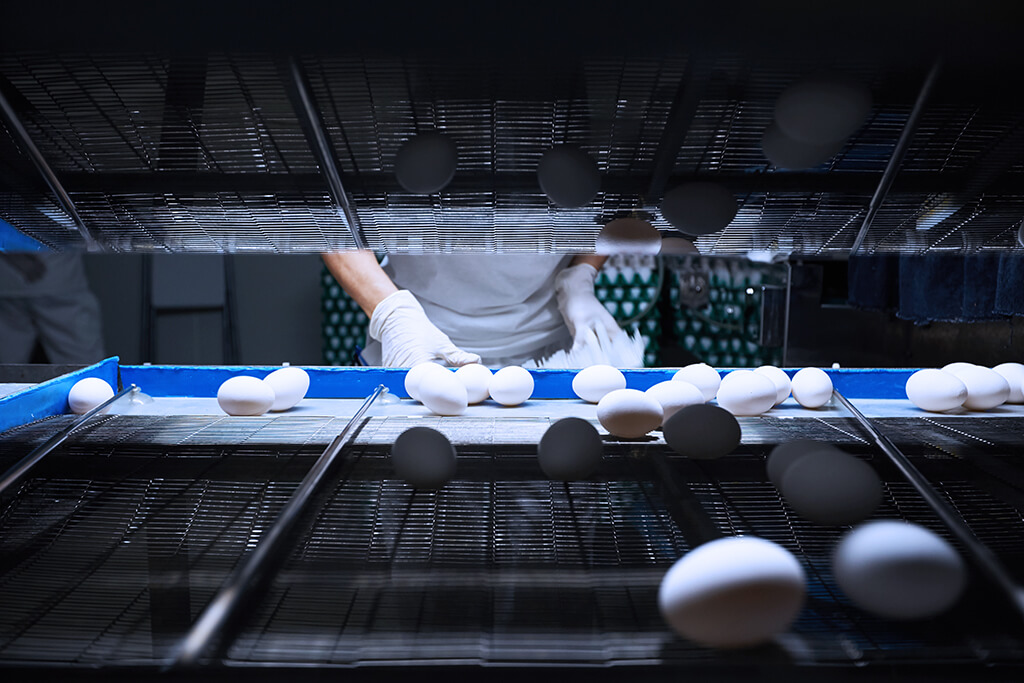

In addition to the production of SPF eggs, our company produced clean eggs. The clean egg or vaccine egg is an egg with a lower immunity status than SPF eggs, and is primarily used for the production of inactivated vaccines for poultry. However, eggs of this classification are also used to produce human influenza vaccines produced using conventional technology.

The requirements for broods of laying hens producing vaccine eggs are set forth in Chapter 5.2.13 of the European Pharmacopoeia. The broods' health status was continuously monitored by clinical and laboratory tests in accordance with pharmacopoeial requirements.